Products

Latest Products

Disposable Boot Cover Waterproof

Classification:

Keyword:

Overview Introduction

Product Details Introduction

Disposable boot cover waterproof

Advantage:

1. light weight,latex free,dust proof

2. Stitching Sewing

3. Fabric weight,Size,Color,Packing design can be customized.

|

Fabric weight |

PP+PE42gsm |

|

Color |

blue |

|

Size |

50*42cm |

|

MOQ |

100, 000PCS |

|

Function |

water proof, personal protection, medical protection |

|

Packing |

50pcs/bag, 10bags/500pcs/carton |

|

Capability |

100, 000pcs/day |

|

Delivery time |

Around 15 days |

|

Applications |

industry, home care, food processing, hospital, clean room and lab |

What makes our product unique?

All our products are researched and developed by our professions with focus on utility and reliability in the disposable items. We offer the essential supplies that doctors professionals need on a daily basis, but are also ready to customize products according to our customers’ specifications and budgets.

Packing:

Disposable boot cover waterproof ,50pcs/bag, 10bags/500pcs/carton,size: 55*28*36cm

Features of disposable medical boot covers

The filter barrier principle of disposable medical boot cover includes Brownian diffusion, interception, inertial collision, gravitational sedimentation, electrostatic adsorption, etc. It is mainly undertaken by the intermediate filter layer. The key lies in the electret treatment technology of the intermediate layer of meltblown nonwoven, while the barrier effect of the inner and outer layers is very small and only plays the role of waterproof, support and molding protection. In addition, there are disposable medical boot covers that use multi-layer polypropylene meltblown nonwoven as the intermediate filter layer. In terms of raw materials, polypropylene is the main component of spunbond and meltblown fabrics for disposable medical boot covers. The meltblown layer usually requires high fluidity, so polypropylene with a high melt index is chosen, while the spunbond layer requires high strength, and polypropylene with a low melt index is generally used.

Disposable medical boot covers can effectively block microorganisms and prevent the penetration of body fluids to reduce cross-infection. Most disposable medical boot covers are made of nonwoven fabric that is laminated, compounded and coated to meet the standard requirements for impermeability and microbial barrier. There are usually polypropylene spunbond, polyester and wood pulp composite spunlace, polypropylene staple fiber (spunbond-meltblown-spunbond) nonwoven, and some composites of nonwoven and microporous breathable membranes.

Polypropylene spunbond nonwoven and polyester fiber and wood pulp composite spunlace nonwoven have high breathability, but low hydrostatic pressure resistance and poor antiviral effect, so they are not used as disposable medical boot cover materials alone, and can be used for common protective items such as disinfection cloth. Polypropylene staple fiber nonwoven fabric is fluffy and soft, with low filtration resistance, high filtration efficiency, and strong hydrostatic pressure resistance. After anti-alcohol, anti-blood, anti-oil and anti-static finishing, it can meet the needs of different applications. Polymer coated fabric has excellent water resistance and antibacterial and antiviral properties, and can be reused. However, a large amount of sweat cannot be discharged when worn, and wearing comfort is poor. Polyethylene or polytetrafluoroethylene breathable film/nonwoven composite material has good barrier to bacterial particle penetration and liquid penetration, has good tensile strength and breathability, can withstand disinfection treatment, and is widely used as chemical protective clothing.

Product Details Display

Factory Show

We provide ourselves on Quality Management System, which centers around our Quality policy: Customer satisfaction is always our mission and goals.

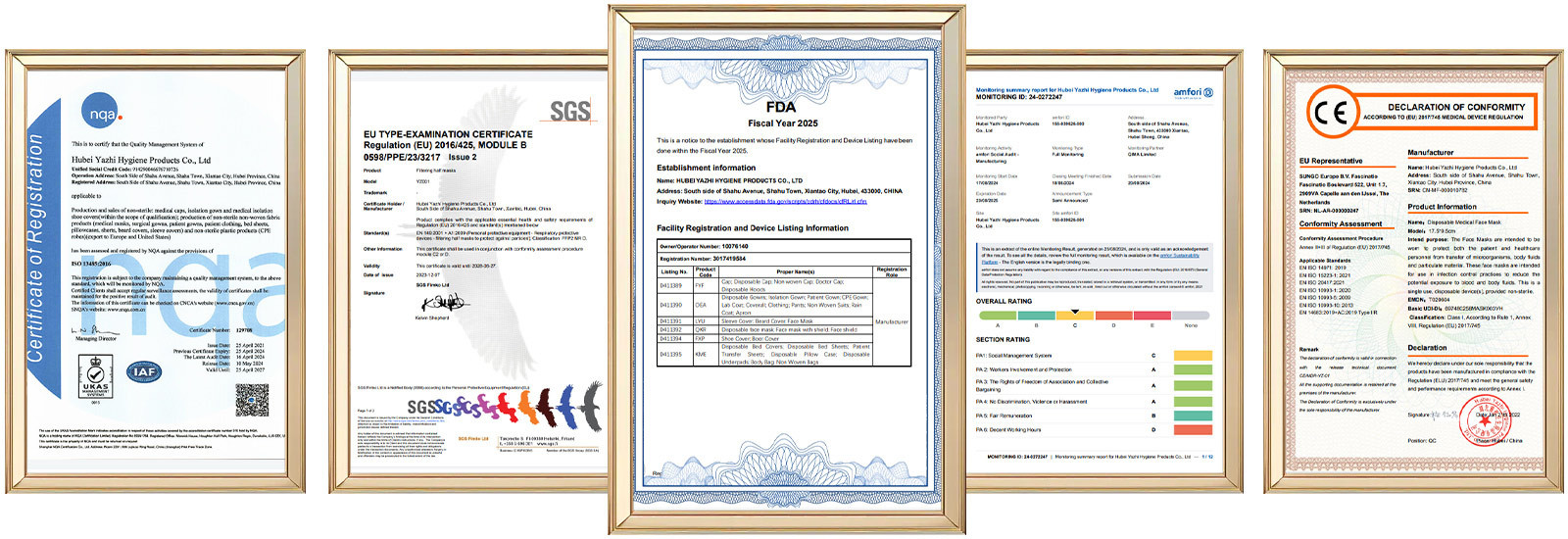

Certificate

FDA, CE, ISO13485,ISO9001,ISO14001, and related SGS TUV etc test reports for most of our products.

Certificate

Germany —

MEDICA & A+A

USA —

FIME , NSC

Singapore —

OSH & MEDICAL FAIR ASIA

Japan —

MEDICAL

UAE —

Arab Health Care

China —

Canton Fair & CMEF & CiOSH

Over 18 years of development, Yazhi company has become more and more mature. Currently we attend exhibitions around the world every year to show our products to people in need.

FAQ

How many face masks are in one box?

Usually, 50pcs in one box, 40boxes/ in one carton, in total 2000pcs in one carton.

How many face mask machines do you have?

We have more than 20 machines, which can have 2,000,000pcs capacity per day.

Can you do other size for face masks?

Yes, we can do normal size 17.5*9.5cm, 14.5*9.5cm, 12.5*8.5cm, and other size also available, depends on your needs..

Which style do you have?

We have ear loop style, head loop style, and cap with face mask style and face mask with shield style.

Do you accept customization?

Yes, we accept customization. We can do logo on face mask if you need. also can do logo on packing as your liking.

Inquiry

English

English English

English Español

Español Português

Português اللغة العربية

اللغة العربية