Products

Disposable Waterproof Bed Sheet

Classification:

Keyword:

Overview Introduction

Water proof and hard to break when used correctly No irritation or stimulation to the user's skin With light weight, it is easy to take out and put it Latex free, non toxic, soft touch, breathable, comfortable, eco-friendly, skin friendly Any color or size you want can be customized

Product Details Introduction

Characteristic

Water proof and hard to break when used correctly

No irritation or stimulation to the user's skin

With light weight, it is easy to take out and put it

Latex free, non toxic, soft touch, breathable, comfortable, eco-friendly, skin friendly

Any color or size you want can be customized

Specification

|

Fabric material&weight |

PP+PE35gsm or customized |

|

Fabric color |

Blue or customized |

|

Size |

80×190cm 90×200cm 100×210cm size can be customized |

|

MOQ |

10, 000pieces |

|

Packing design |

OEM or standard |

|

Packing |

10pieces/bag, 50pcs/carton |

|

Capability |

100, 000/day |

|

Delivery time |

7-15days |

|

Applications |

Beauty saloon, massage, tattoo, dentist's |

Packing:

10pieces/bag, 50pieces/carton, carton size: 40*28*28cm

Product Details Display

Factory Show

We provide ourselves on Quality Management System, which centers around our Quality policy: Customer satisfaction is always our mission and goals.

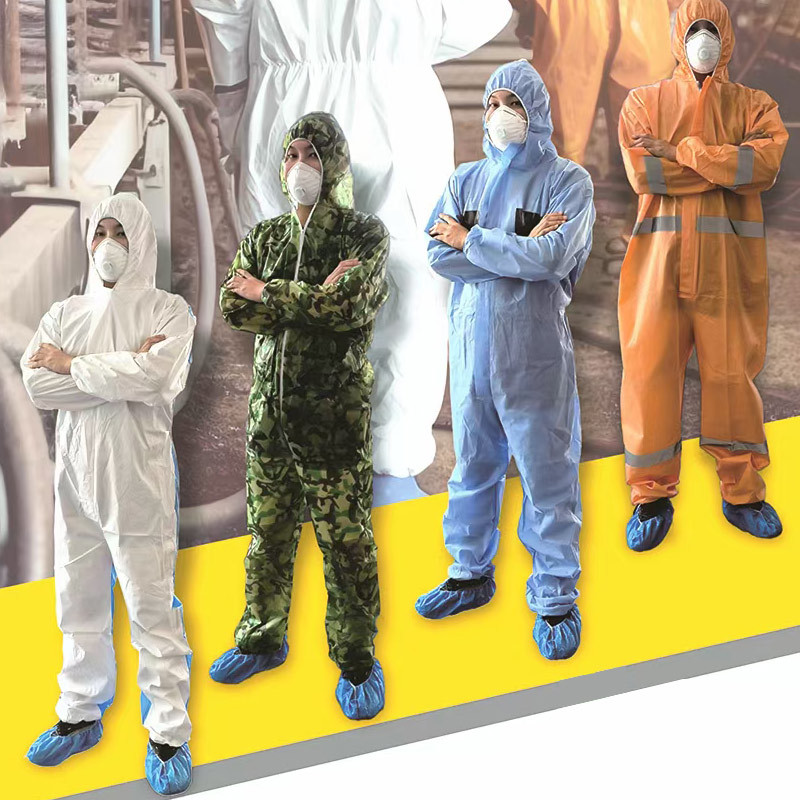

Featured Products Categories

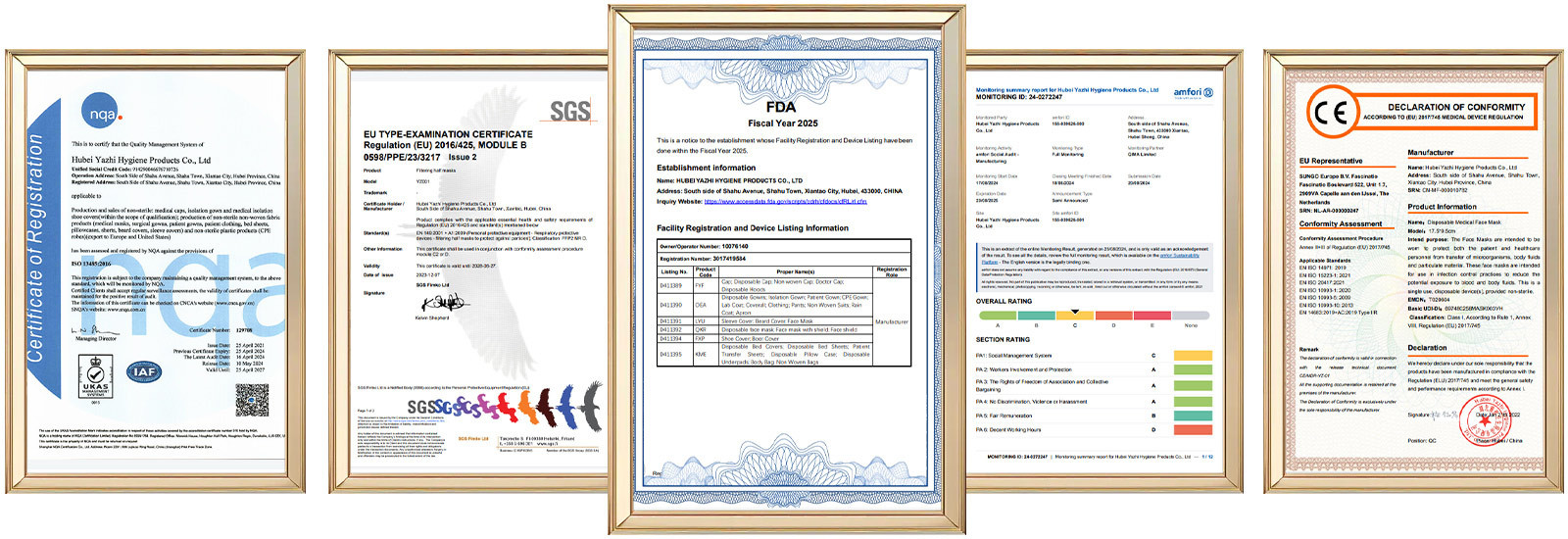

Certificate

FDA, CE, ISO13485,ISO9001,ISO14001, and related SGS TUV etc test reports for most of our products.

Certificate

Germany —

MEDICA & A+A

USA —

FIME , NSC

Singapore —

OSH & MEDICAL FAIR ASIA

Japan —

MEDICAL

UAE —

Arab Health Care

China —

Canton Fair & CMEF & CiOSH

Over 18 years of development, Yazhi company has become more and more mature. Currently we attend exhibitions around the world every year to show our products to people in need.

FAQ

How many face masks are in one box?

Usually, 50pcs in one box, 40boxes/ in one carton, in total 2000pcs in one carton.

How many face mask machines do you have?

We have more than 20 machines, which can have 2,000,000pcs capacity per day.

Can you do other size for face masks?

Yes, we can do normal size 17.5*9.5cm, 14.5*9.5cm, 12.5*8.5cm, and other size also available, depends on your needs..

Which style do you have?

We have ear loop style, head loop style, and cap with face mask style and face mask with shield style.

Do you accept customization?

Yes, we accept customization. We can do logo on face mask if you need. also can do logo on packing as your liking.

Inquiry

Language

Language English

English Español

Español Português

Português اللغة العربية

اللغة العربية